w3c

SLICE3D FERMERA EXCEPTIONNELLEMENT SES PORTES DU 6 MAI AU 10 MAI 2024 INCLUS.

Say something...

Nothing found. Please repeat.

Unsupported browser. Sorry...

|

Trouvez de nombreux accessoires de scanner 3D utiles tels que des sprays de numérisation, des marqueurs, des plateaux tournants et des modules complémentaires pratiques pour les numérisations couleur. |

|

Chez Slice3D, votre partenaire en impression 3D à Gembloux, vous achetez avec confiance et bénéficiez d'un service après-vente de proximité. Envie de plonger dans l'impression 3D ? Nous guidons les entreprises vers la technologie adaptée, le matériel idéal et l'implémentation de leur parc d'impression 3D. Faites le bon choix dès le départ. |

Facilitez l'acquisition de votre imprimante 3D ! Grâce à notre partenaire Grenke Lease, nous vous proposons une solution de financement aux entreprises qui veulent investir dans la technologie 3D sans pression immédiate sur la trésorerie. Confiez-nous vos projets et bénéficiez d'une impression 3D de haute qualité, réalisée selon vos besoins spécifiques. Nous pouvons imprimer des pièces de 1x1x1m en une seule pièce. |

Service local

Service local

Un service personnalisé en français

Politique de livraison

Politique de livraison

Livraison rapide en Belgique et en France

Technical support

Technical support

Technical support and warranty directly from Slice3D

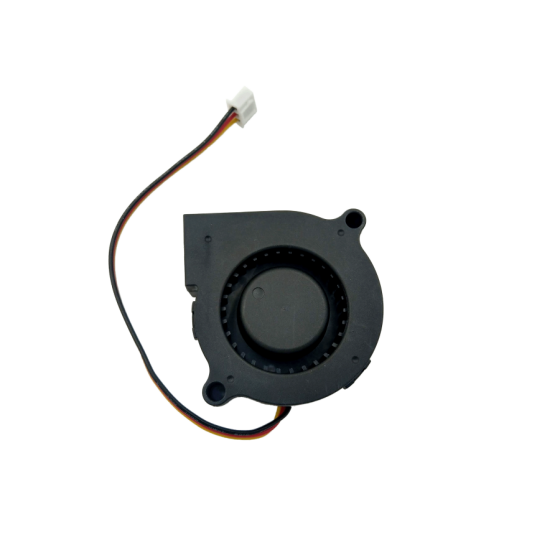

Filament Cooling Fanfor Flashforge Guider II.

24V, 0.10A.

Does not include mounting bracket.

Boxed:

Sticky Header:

Sticky Add To Cart

Sticky Footer:

Font: