w3c

Local service

Local service

Personalised service in French

Delivery policy

Delivery policy

Fast delivery in Belgium and France

Support technique

Support technique

Support technique et garantie directement chez Slice3D

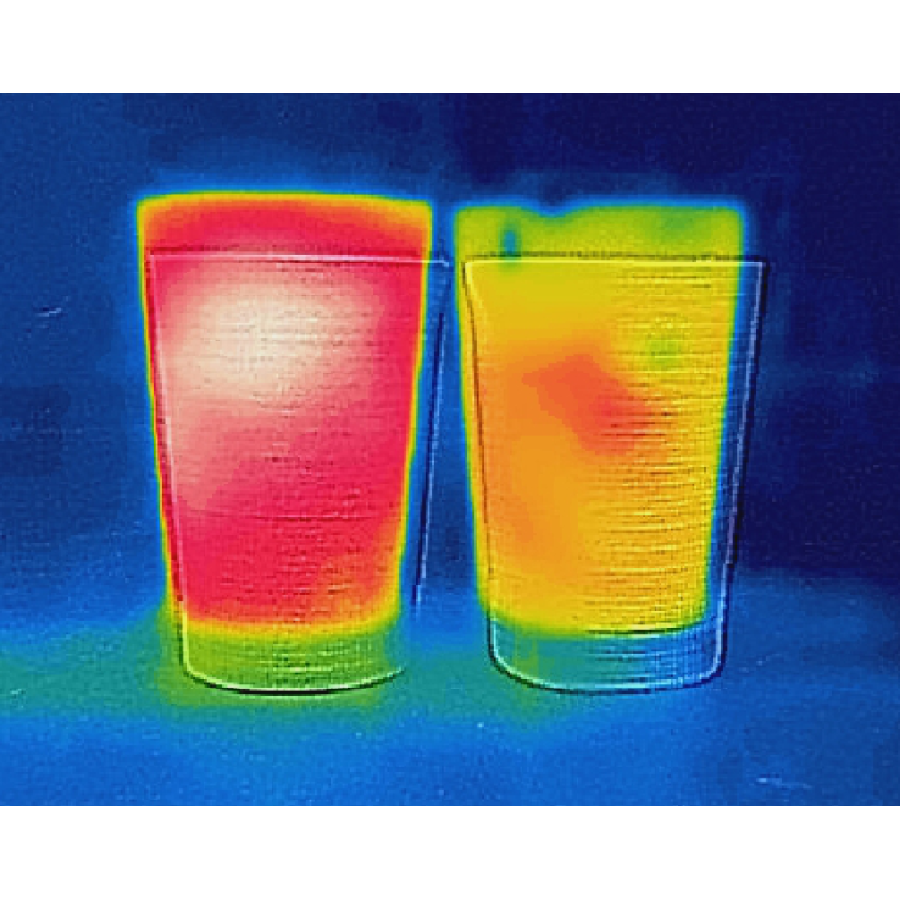

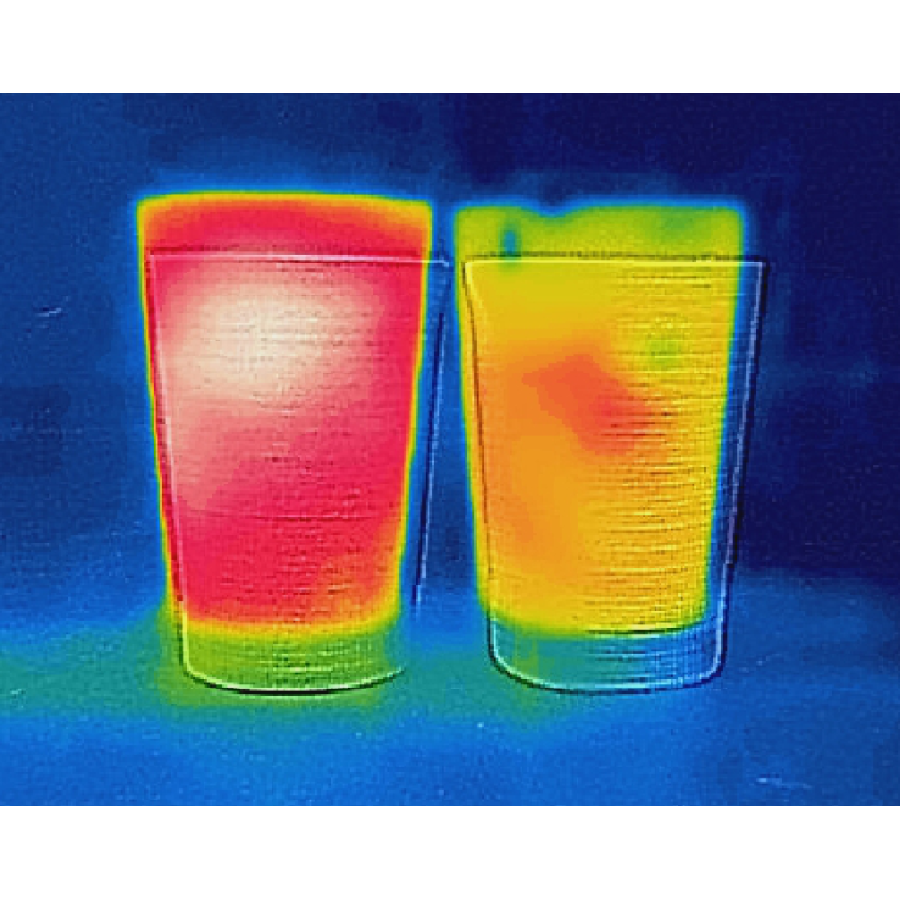

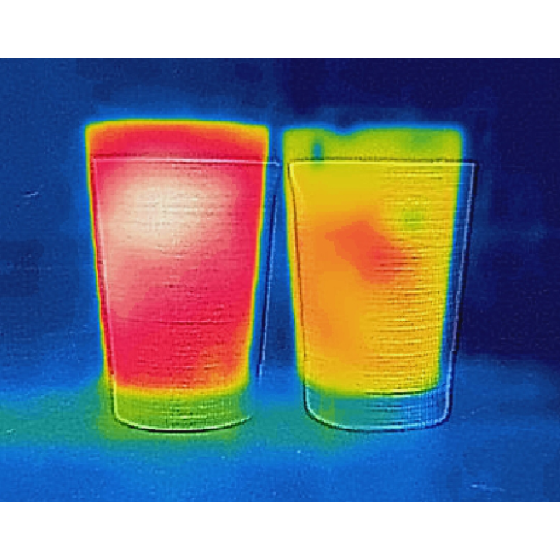

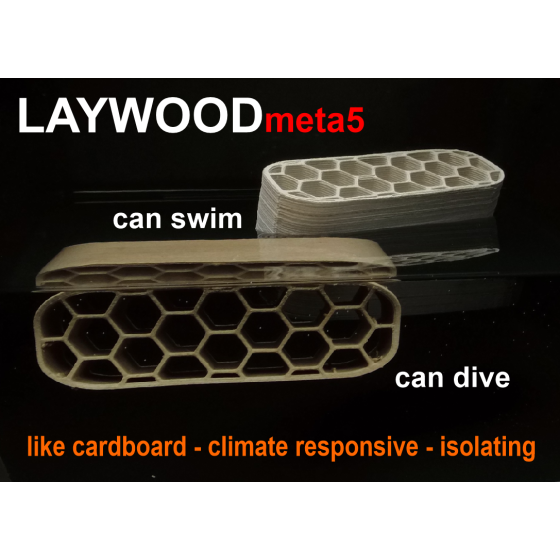

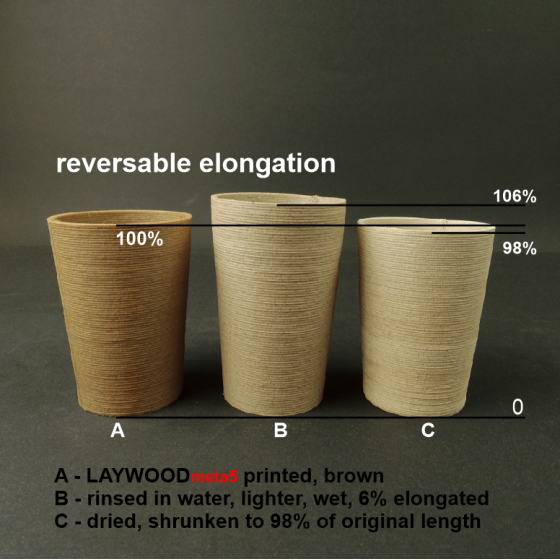

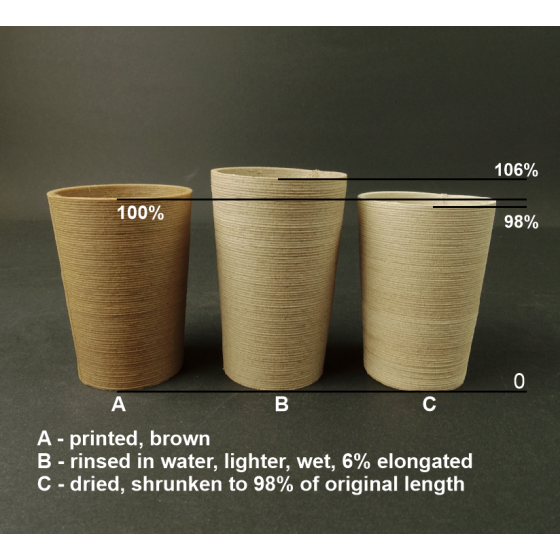

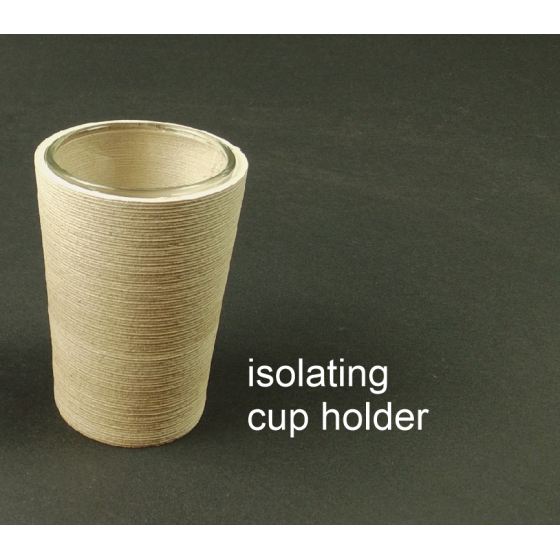

Similar to cardboard, objects printed with LAYWOODmeta5 have a rough surface with a micro-porous structure that can quickly absorb water and thus expand. This process can be reversed by drying in an air stream.

You probably remember LAYWOO-D3 - the first wood-filled filament that allowed objects with light-dark annual rings to be printed very wood-like. Compared to LAYWOOD, the new material is porous, so it has a lower density (something like balsa wood) that is about half that of standard filaments. Rinsing in water over two days creates open, mycelium-like cell structures. This causes printed objects to float on water - unlike unrinsed parts which have a density comparable to other thermoplastics.

On the 3D printer, the filament is easy to process and adheres to the unheated print bed without warping. The printing temperature should be between 235 and 250°C. By the way, the material can also be labeled with any type of ink after printing.