Welcome to the exciting world of Fusion360, the benchmark for 3D modelling and computer-aided design. At 3DTECHLAB, we're delighted to accompany you on this adventure of learning and exploration.

At 3DTECHLAB, we firmly believe in the power of hands-on learning. That's why, at the end of our advanced module, each participant will leave not only with enhanced modelling skills for 3D printing, but also with an essential tool for putting those skills into practice: their own 3D printer. Yes, you read that right!

At the end of the "Advanced Fusion360" training course, we're giving away a 3D printer worth at least €400 to all participants, enabling them to immediately deepen their passion, experiment and bring their projects to life. It's our way of thanking you for your commitment and encouraging you to continue your journey into the world of 3D.

Fusion 360 training - Introduction

Discover Fusion 360 with our introductory course.

Create 3D models right from the start.

Fusion 360 training - Advanced

Master Fusion 360 with our advanced training.

Software description

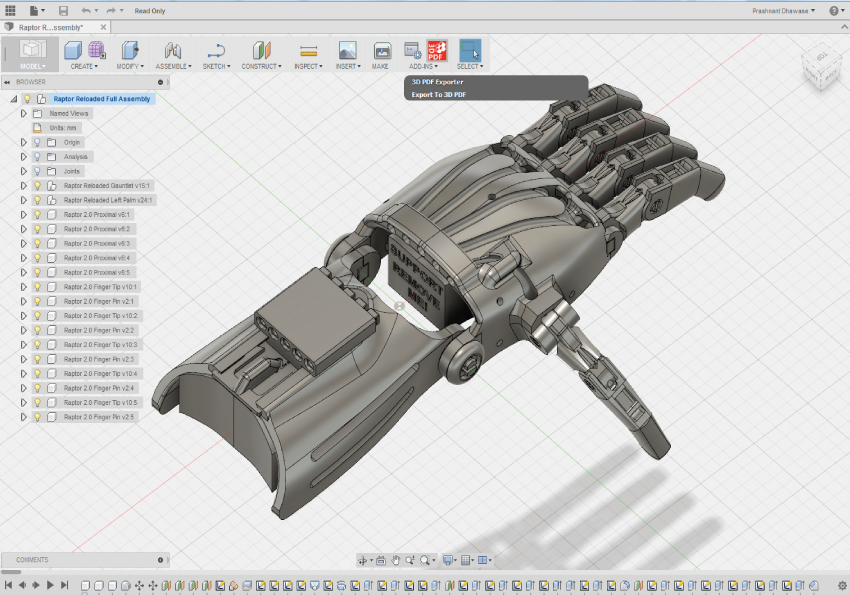

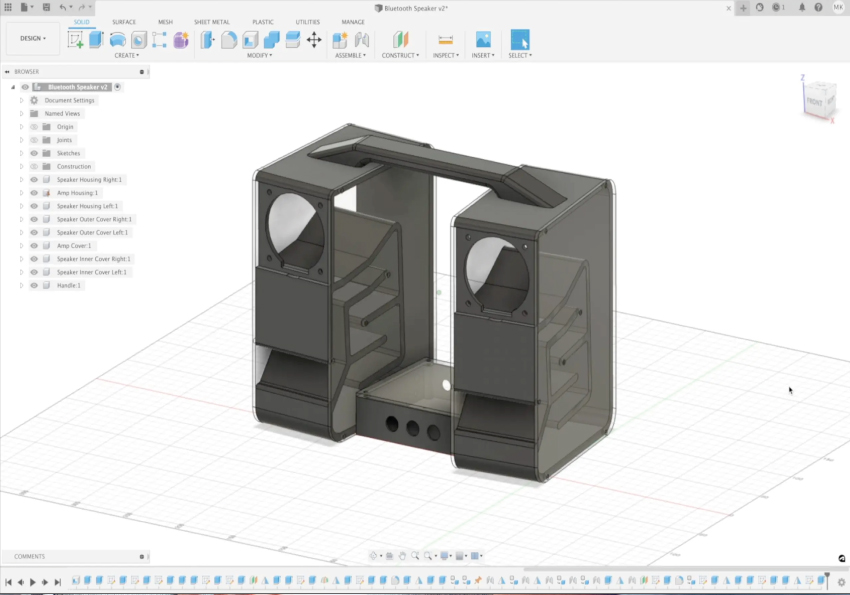

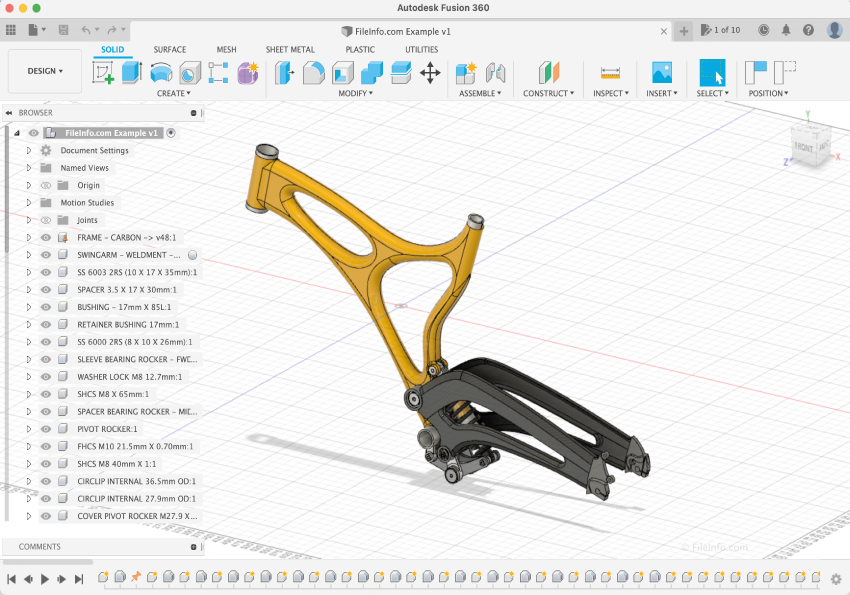

Fusion 360 is computer-aided design (CAD) software developed by Autodesk. It sets itself apart from traditional CAD solutions by offering a complete set of design, engineering and manufacturing tools in a single cloud-based platform.

Designed for professionals, students and enthusiasts, it adapts to the needs of modern designers in a variety of fields, from industrial design to mechanics, electronics and additive manufacturing.

In conclusion, Fusion 360 is more than just CAD software. It is a revolution in the world of design, offering integrated solutions for modern design and manufacturing challenges.

For professionals looking to optimise their workflow, adopt an innovation-focused approach and collaborate effectively as a team, Fusion 360 is the obvious choice.

Benefits of the software

Perfect integration

Fusion 360 integrates design, simulation, rendering and manufacturing in a single software package.

Flexibility

With its hybrid modelling capability, Fusion 360 is equally suited to artistic projects and complex mechanical designs.

Collaboration

Work with several people on the same project, view changes in real time and share your designs easily.

Career opportunities

With a command of Fusion 360, the opportunities are vast: product design, mechanical engineering, animation and graphics rendering, prototyping, manufacturing, and much more.

Areas of activity concerned

Industries such as aerospace, automotive, jewellery, architecture and even entertainment are increasingly turning to Fusion 360 to meet their needs.

Fusion 360 training - INTRODUCTION

Duration: 5 days

Timetable : 9am to 5pm

Lesson plan

Home and Introduction

- Introduction of participants and instructor

- Presentation of the course structure

Introduction to Fusion 360

- History and development of Fusion 360

- Advantages of Fusion 360 over other CAD software

User interface

- Exploring the Ribbon, toolbar, browser and timeline

- User interface customisation

Navigation and Display

- Manipulating the 3D view (rotating, zooming, moving)

- Using predefined views

Parametric Modelling Concepts

- Introduction to constraint-based modelling

- The difference between parametric and direct modelling

Creating Sketches

- Using basic drawing tools

- Applying geometric constraints

Basic features

- Extrusion, revolution, scanning, smoothing

- Modification operations : offset, chamfer, rounding

Assemblies

- Introduction to components and assemblies

- Use of joints and connections

Direct Modelling

- Introduction to unconstrained modelling

- Benefits and usage scenarios

Creation of Parametric Components

- Using user parameters

- Editing and modifying parameters

T- Sculpture tools.Spline

- Introduction to organic modelling

- Manipulating T-Spline shapes

Advanced Modelling Techniques

- Using schematics

- Modelling from reference images

Principles of Simulation

- Importance of simulation in design

- Types of simulations available in Fusion 360

Stress Simulation

- Configuration and running a stress simulation

- Interpreting the results

Rendering and Visualisation

- Introduction to Fusion 360 rendering tools

- Creating photo-realistic renders

Preparation for Manufacturing

- Integrated CAM tools

- Preparation process for 3D printing

Collaboration and Sharing

- Using Fusion 360's collaboration features

- Sharing projects and designs with other users

Review and Practice

- Q&A session.answers

- Practical workshop: creating a small project from A to Z

Conclusion and Evaluation

- Retrospective on the training week

Formation Fusion 360 - AVANCÉ

Duration: 5 days

Timetable : 9am to 5pm

Lesson plan

Quick review of Fundamentals

- Summary of key skills from introductory course

Hybrid Modelling

- Combining parametric and direct modelling for. 3D printing

- Surface modelling for complex shapes

Optimisation for Printing

- Weight reduction without compromising strength

- Design for minimal assembly postprinting

Designing Assemblies for 3D Printing

- Printable joining and assembly techniques

Fastening techniques

- Designing clips, tenons, and mortises for assembly

- Use of inserts and other non-printable components

Strength and Durability testing

- Simulations to assess the strength of printed models

Printability validation

- Detecting and solving common printing problems

- Support and reinforcement techniques for printing

Material Oriented Design

- Understand and use the advantages of different printing materials

Topological Optimisation

- Use material reduction while maximising strength

- Create organic and optimised designs for 3D printing

Finishing for Printing

- Smoothing and surface preparation techniques

- Preparing files for different types of 3D printers

Post-processing techniques.processing

- Methods for improving the finish and appearance of printed parts

- Assembly and integration of printed parts

Final project and feedback

- Integrator project focusing on advanced modelling for 3D printing

- Q&A session and evaluations

3D printer handover and closing